About: Cargill provides food, agriculture, financial and industrial products and services to the world.

The problem: Cargill required industrial gas pipework to be decommissioned at one of their chemical plants.

This was so the pipework could be disconnected and two condemned steam boilers could be removed.

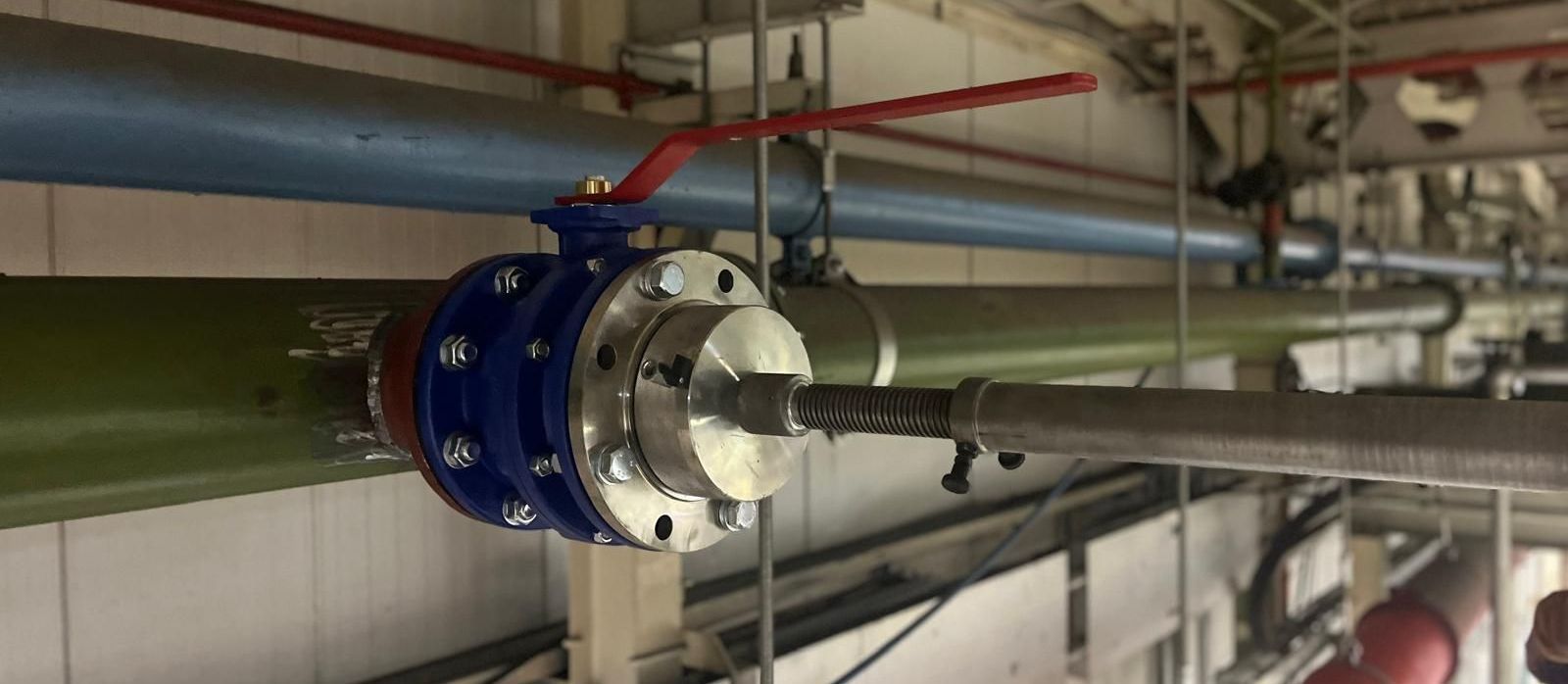

Our solution: As specialist industrial Gas Safe engineers, Ormond Pipework Services Ltd, used nitrogen to purge the gas inside the existing pipework.

We purged out 4 cubic meters of natural gas and monitored the air to gas ratio. We then issued a commercial Gas Safe certificate to ensure the pipework was clear of gas and was safe to work on. Once the disconnections were complete, our engineers returned to perform a gas tightness test and direct purge.

Finally, another Gas Safe certificate was issued to ensure the commercial gas installation was safe to use.

Tasks involved:

Indirect gas purge

Gas tightness test

Direct gas purge

Industrial Gas Safe certificate

We have used Ormond's hot tapping services for over 20 years, and will continue to do so

Ormond Pipework made my job easy and I would highly recommend them

Ormond have done our hot tapping for the last 10 years, we trust them to always get the job done.

Very professional. We choose Ormond every time for our pipework.