The problem: Electric Glass Fibre UK had invested in two new gas-powered furnaces.

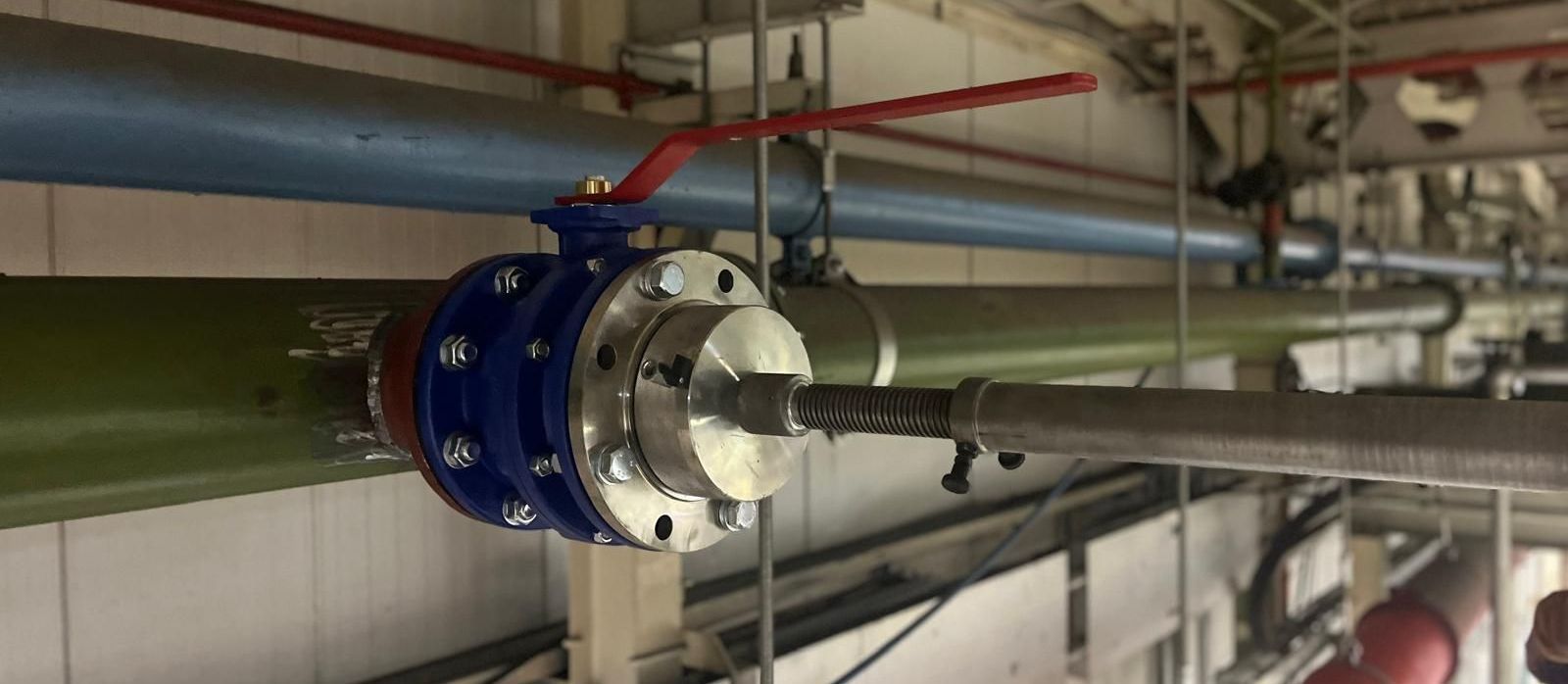

Fifty meters of 4”- 2” mild steel pipework was required to supply the new furnaces with natural gas.

Our solution:

Our commercial gas engineers were called in to install the new gas pipework.

Both welded and screwed methods were used in order to fit the new pipework.

Once the installation was complete a commercial gas tightness test and direct purge were undertaken.

After a successful test and purge, a Gas Safe certificate was issued, ensuring the new industrial gas pipework was ready to use.

Tasks involved:

Steel pipework fabrication

Screwed pipework installation

Gas purging

Gas tightness test

Gas pipework commissioning

Gas Safe certificate

We have used Ormond's hot tapping services for over 20 years, and will continue to do so

Ormond Pipework made my job easy and I would highly recommend them

Ormond have done our hot tapping for the last 10 years, we trust them to always get the job done.

Very professional. We choose Ormond every time for our pipework.