The problem: One of BT’s warehouses required part of their gas main to be purged, decommissioned and cut off.

Their industrial gas installation was large and complex. Turning the gas off to the entire site was problematic because the old gas pipework may not have passed a tightness test.

What’s more, BT required their gas to remain live in order to avoid any downtime or disruption.

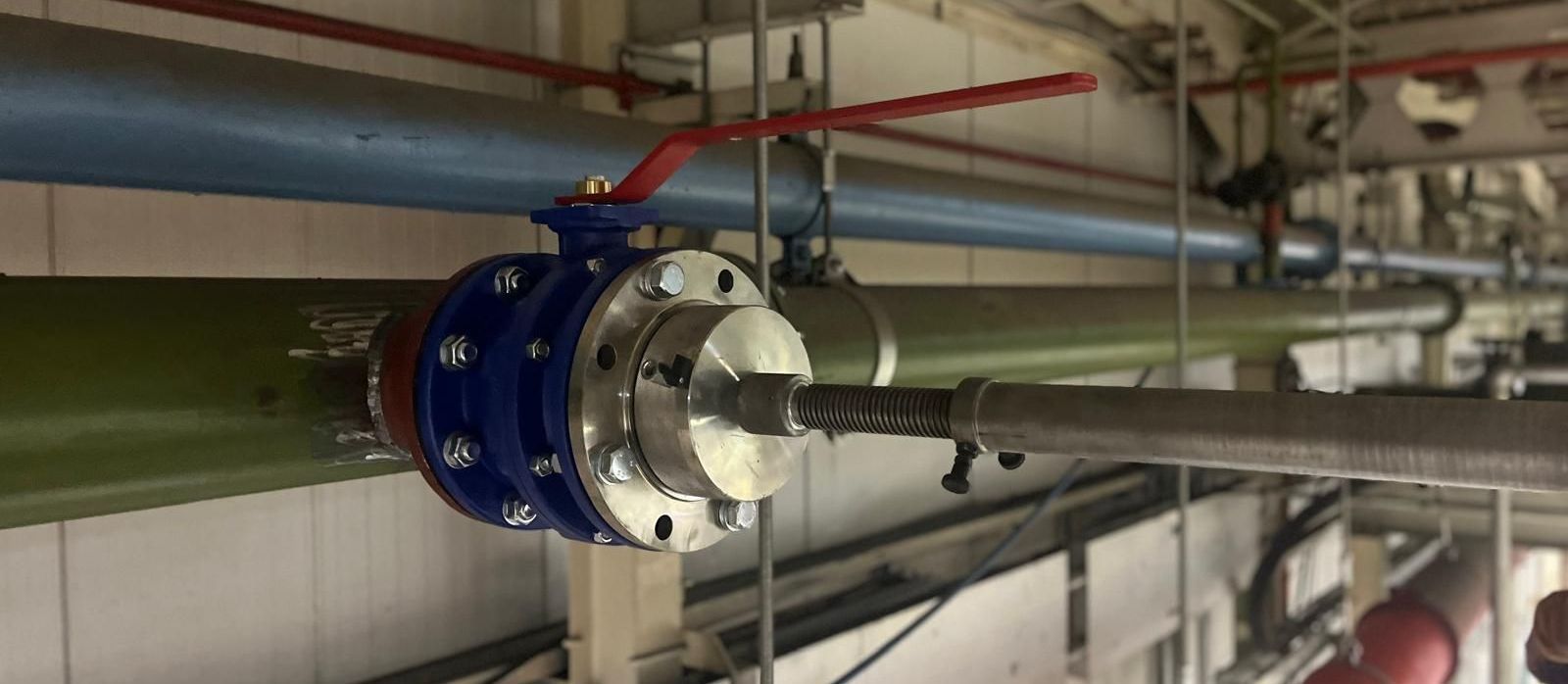

Our solution: To avoid turning off appliances and tightness testing, a line stopping procedure was recommended in order to form a temporary inline valve.

Our commercial Gas Safe engineers were brought in to assist in line stopping the steel 4” gas pipework.

Hot tapping a 1” connection was also required in order to form a purge point.

We welded a 4” and 1” branch to the existing gas pipework.

Once the gas supply was isolated, we nitrogen purged the existing pipework.

The decommissioned pipework was then disconnected and a Gas Safe certificate was issued.

Tasks involved:

Line stopping

Hot tapping/under pressure drilling

Welding

Indirect gas purge

Commercial Gas Safe certificate

We have used Ormond's hot tapping services for over 20 years, and will continue to do so

Ormond Pipework made my job easy and I would highly recommend them

Ormond have done our hot tapping for the last 10 years, we trust them to always get the job done.

Very professional. We choose Ormond every time for our pipework.