The problem: A gas leak was discovered coming from an existing underground gas installation at Forkers.

Forkers required a new gas installation both above and underground in order to eliminate leaks of the existing pipework.

Our solution: Firstly, a gas tightness test was done to establish the severity of the gas leak.

Because the leak test had failed safety standards, it was decided a new gas supply was to be installed.

An indirect gas purge was undertaken so that the existing installation could be decommissioned.

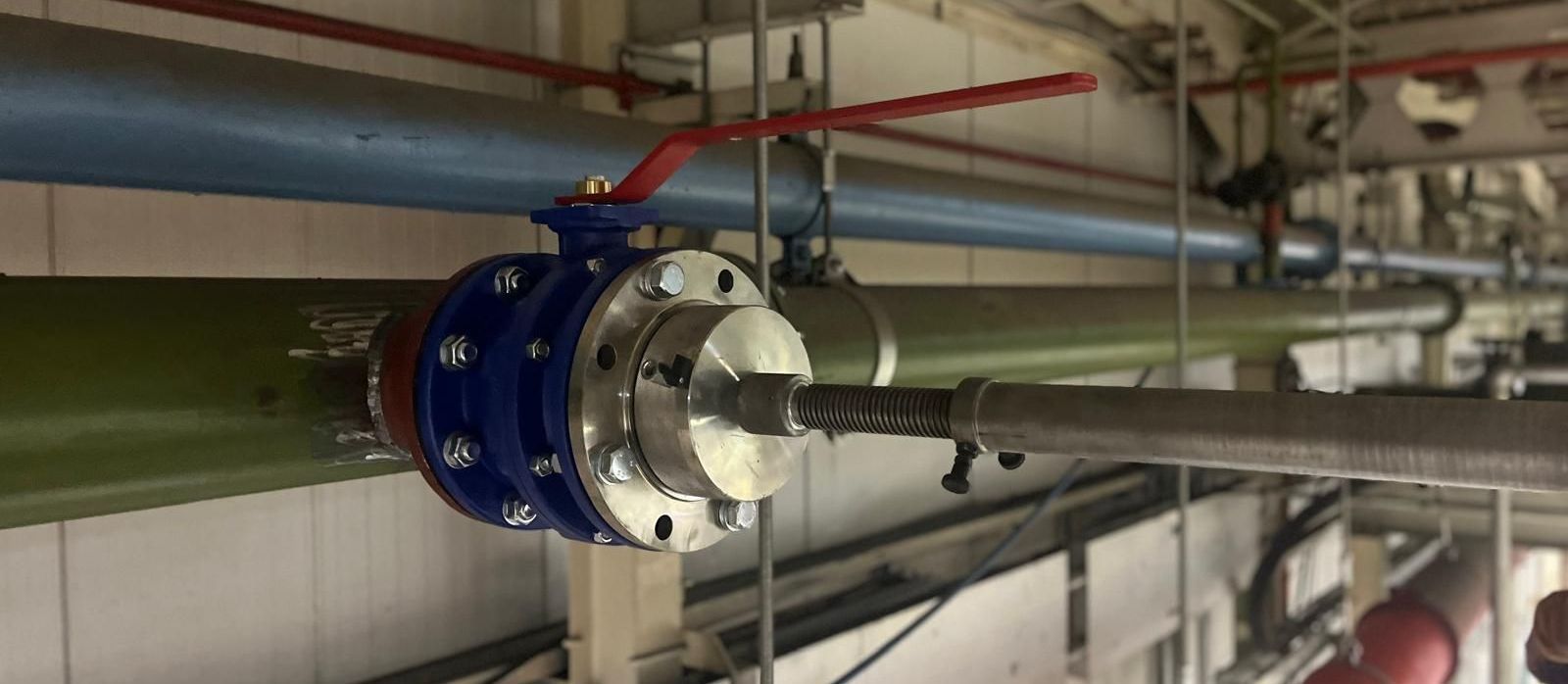

Using but fusion technology, Ormond installed 100M of 108mm MDPE pipework. Our engineers fitted the MDPE and transitioned to 4”steel above ground level.

Once the installation was complete, our gas safe engineers did a tightness test and direct purge.

Finally, a Gas Safe certificate was issued to ensure the commercial gas installation was up to standards.

Tasks involved:

Underground MDPE

Steel pipework fabrication

Gas purging services

Gas tightness test

Gas Pipework Decommissioning

Gas pipework commissioning

Industrial Gas Safe certificate

We have used Ormond's hot tapping services for over 20 years, and will continue to do so

Ormond Pipework made my job easy and I would highly recommend them

Ormond have done our hot tapping for the last 10 years, we trust them to always get the job done.

Very professional. We choose Ormond every time for our pipework.